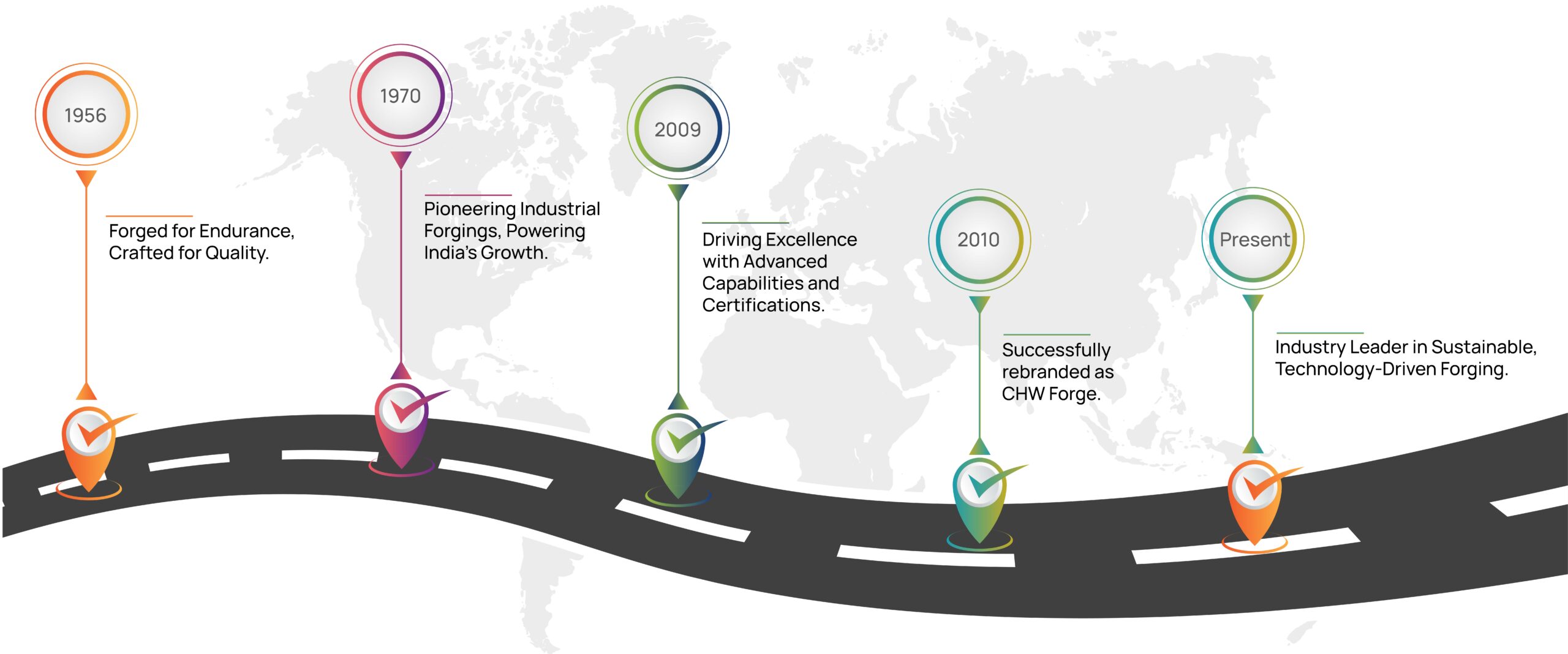

Founded, focused on endurance and quality.

CHW Forge, formerly known as Chaudhry Hammer Works, was established in 1956. It is one of South Asia’s leading forging companies, renowned for its exceptional quality and on-time delivery. Our specialized skills and vast experience make us pioneers in forging manufacturing, and our products set a benchmark for excellence across the industry.

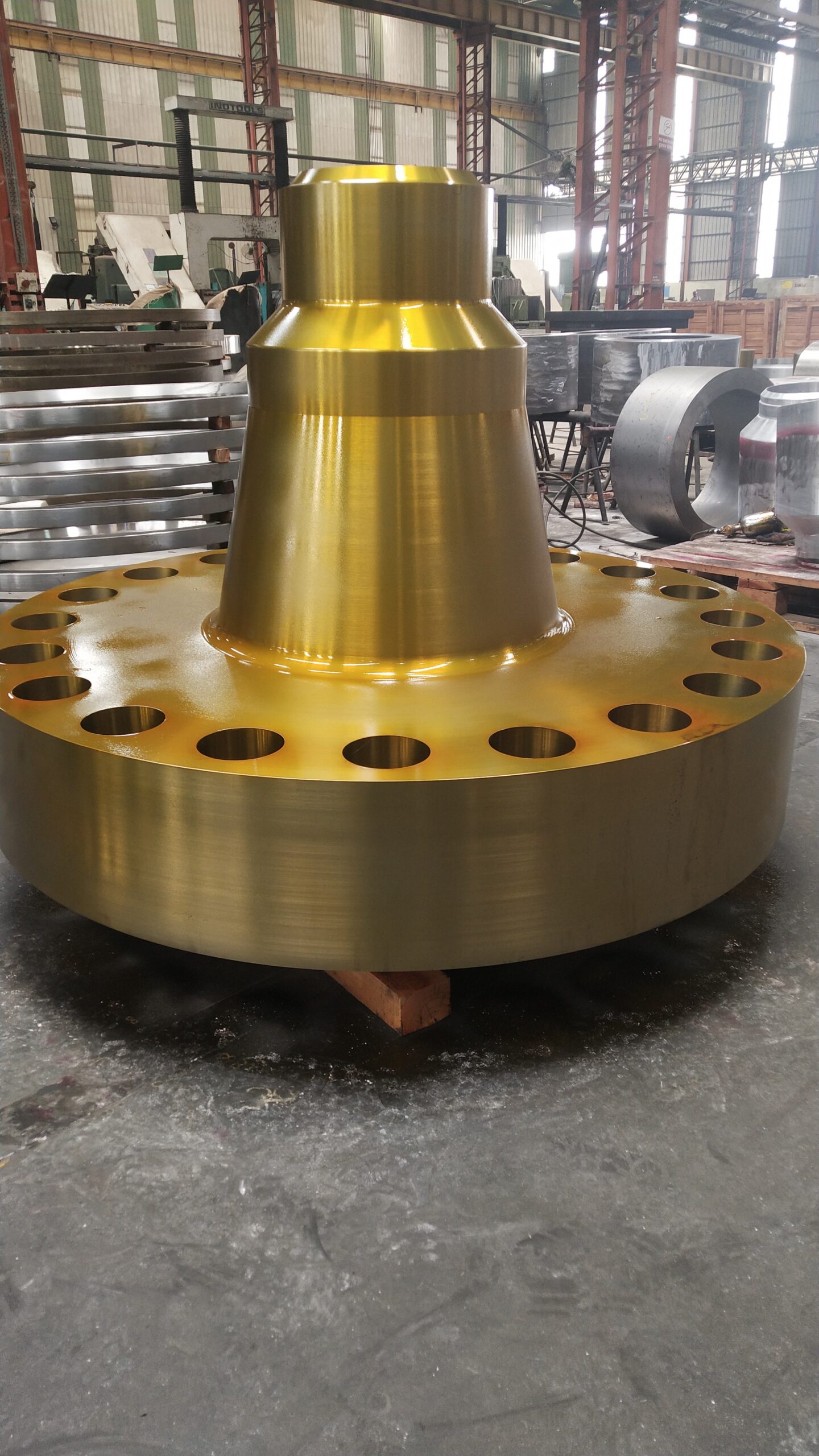

CHW Forge is a leading Indian manufacturer and supplier of forged components, offering premium-grade forgings in carbon steel, alloy steel, stainless steel, duplex steel, aluminum & titanium alloys. Supported by a robust global supply network, we cater to multiple industries with consistent quality, reliability, and engineering excellence.

Founded, focused on endurance and quality.

Started industrial forgings, supporting India’s growth.

Adopted integrated ERP systems and earned customer trust

Built advanced capabilities and certifications

Rebranding to CHW Forge, marking a new chapter.

Industry leader in sustainable, technology-driven forging.

We operate a 4 MW installed solar power capacity and further supplement our energy requirements by sourcing additional power from renewable energy providers.

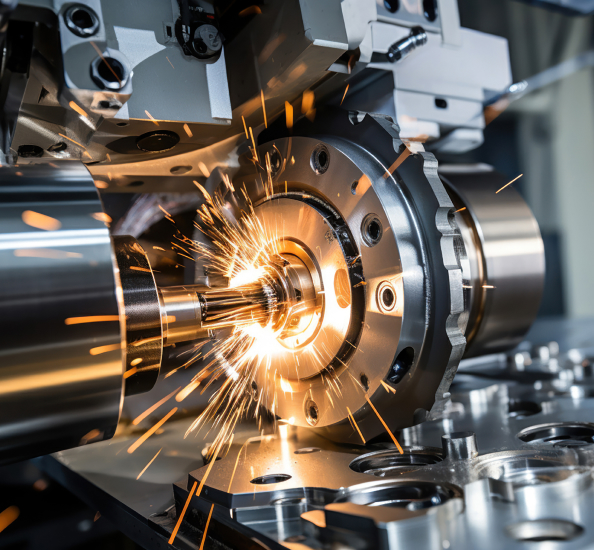

CHW Forge delivers precise, high-quality forgings through advanced manufacturing technologies and rigorous quality control systems.

Spanning 1,60,000 square meters, CHW Forge combines world-class industrial infrastructure with a commitment to sustainability. Around 30% of our land is maintained as lush green cover, reflecting our dedication to eco-friendly practices while driving industrial excellence.

At CHW Forge, we view our suppliers as trusted partners. Through sustainable procurement and a shared commitment to quality, we build strong, collaborative relationships that drive mutual success.”

CHW Forge delivers top-grade steel and aluminum alloys to major sectors such as Oil & Gas, Heavy Earth Moving Machinery, Power, Aerospace and for various Engineering Applications. With quality and speed at the core, we meet the critical demands of today’s high-performance industries.

Our process is designed to maximize efficiency and quality at every stage of production. By integrating advanced technologies and best practices, we ensure seamless workflows.

We begin by thoroughly assessing your requirements and objectives to develop a tailored approach.

Our team collaborates to create detailed project plans, ensuring all aspects of the process.

Utilizing advanced technologies and skilled personnel, we execute the project

We believe in providing clear and upfront pricing to ensure that you understand the value of our services.

“We are sincerely grateful for your warm and gracious welcome.”

Dealing with CHW is always a pleasure!!! CHW team is so very well organised and Dedicated , we feel very happy to deal with them.

Company Interpipe started cooperation with CHW Forge as a round billet supplier in 2013. From the very beginning we were very much impressed.

Stay updated with the latest trends, innovations, and expert insights in the manufacturing and industrial sectors

Work with Us and Experience Precision, Innovation, and Long-Term Success.

Copyright © 2026 All Rights Reserved. Design & Developed by JAK Software